|

Graphite ROD | Graphite BLOCK | Graphite ELECTROD | Graphite FILM | Graphite MOLD | Graphite CRUCIBLE | Graphite ROTOR |

|

|

|

|

|

|

|

|

|

|

|

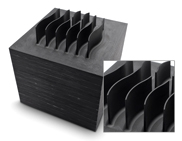

Graphite machining to make up graphite electrode is recognized as easy because there is no cutting resistance of work piece, but high precision and suitable selection of dedicated cutting tools are required. |

|

|

|

|

|

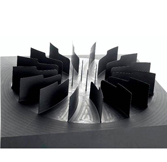

The mold industry makes electrodes from graphite for mold processing. Graphite is flexible and has a high elastic coefficient, so it is suitable for processing into fine shapes. |

|

|

12-21(Geumho-dong 3ga) Geumhosan 10gil Seongdong-gu Seoul Korea |